There’s a bottleneck in denim laser finishing - making the laser file. Designing a laser file is one of the most labor- and skill-intensive parts of the denim finishing process. It can take an experienced designer up to 16 hours of time spent in photoshop per garment!

Our technology uses cutting edge artificial intelligence and machine learning to emulate the way an experienced designer draws a laser design. This gives results made with our web platform a natural, 3-D looking finish. The files generated by our AI-powered platform can be read by any laser system and are easy to modify. Every design made by our software is unique and secure and is 100% yours.

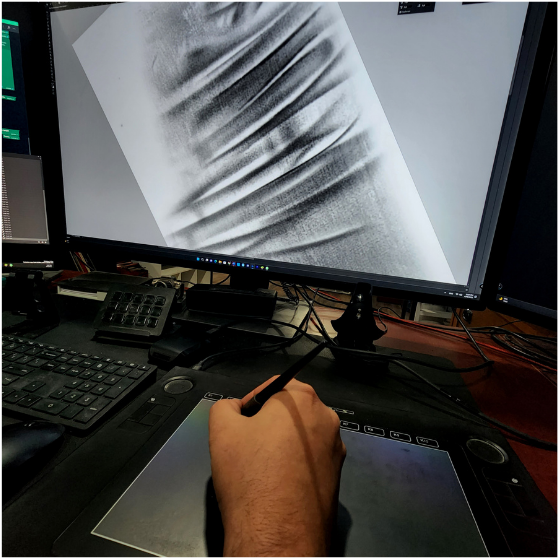

To create a laser file by hand, you first have to photograph an inspirational vintage garment, then open the photographs in image editing software, typically photoshop.

Then, you have to trace out each detail – every whisker, chevron, starburst, and worn area – by hand, taking special care to keep the highlights and shadows in a range that you know works well with the laser to give a realistic-looking effect. This takes a long time! (it also requires a lot of skill and experience)

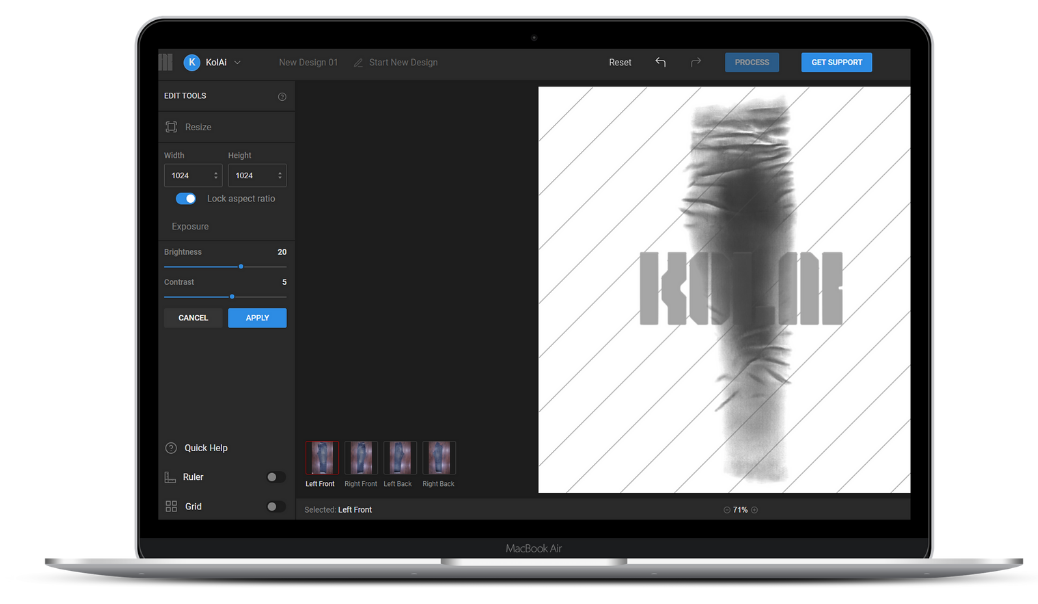

KolAi’s software takes in images of a vintage garments and automatically returns authentic-looking laser designs to mimic the wear on the vintage garments. All that painstaking work of hand-tracing the whiskers and used areas and carefully balancing the highlights and shadows is done automatically with the software.

KolAi’s software was trained using the latest machine learning algorithms with a database of thousands of existing laser designs. The existing designs were created by hand by laser design experts. Our A.I. studied this database, learned how the experts create their designs and how to mimic that process for jeans it hasn’t seen before.

Yes! The software outputs basic raster files (in either .png or .bmp formats) so you can use them with any brand of laser machine.

No! Our software is really good at mimicking the wear patterns of existing vintage garments. However, design teams often don’t want to just mimic existing garments, they have specific feedback and changes they want to make – remove this whisker, make this chevron straighter, add abrasion to the knee, etc… A laser designer is still needed to make these changes, tweaking the output of the software when necessary.

KolAi’s software doesn’t replace laser designers. Rather, it’s a tool that makes their jobs easier and multiplies their productivity. So, they can create 10 designs in a day instead of 1.

Yes! Once you have a base design to work from, it is very easy to make adjustments in photoshop (removing whiskers, adding abrasion, etc.; video example coming soon)

Laser designers often prefer to work with multiple layers (e.g., a base layer to give general abrasion and highlights layer to boost the whiskers) because it can give a more natural-looking result and it makes it easier to make adjustments if necessary with the laser.

Our software only outputs one layer which should work as is. However, it is very easy to use our output to create multiple layers in Photoshop if that is what the laser designer prefers (video example coming soon).

One thing to note is that single layer designs are preferable from the viewpoint of production efficiency because multiple layers means multiple laser markings for a single design which increases production time per garment.