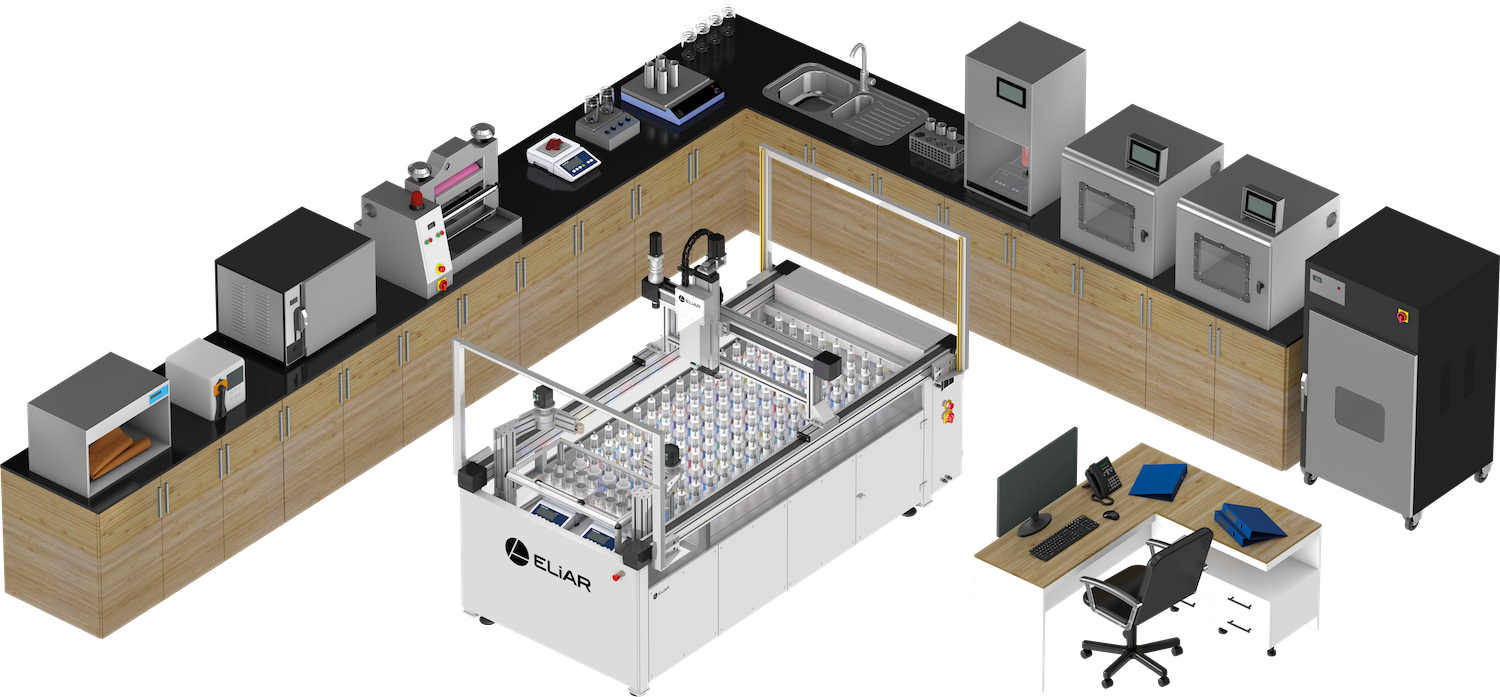

Developed with the engineering and assurance of Eliar,

LABx is built to make your laboratory dyeing process faster and more precise.

Regardless of the size of your enterprise, the raw material you will process and the dyeing method you apply, the first step in obtaining the right color and shade in production is the correct creation of the laboratory dyeing recipe. After the recipe is created, it is necessary to cut the textile surface to be dyed in the laboratory in the right amount, to dissolve the dyestuffs in the prepared recipes with high precision, and to dose these solutions into the dyeing tubes according to the recipes to be studied. Eliar offers the most efficient laboratory automation system, the LABx product family to your service, so that your laboratory dyeing process can be carried out error-free and quickly.

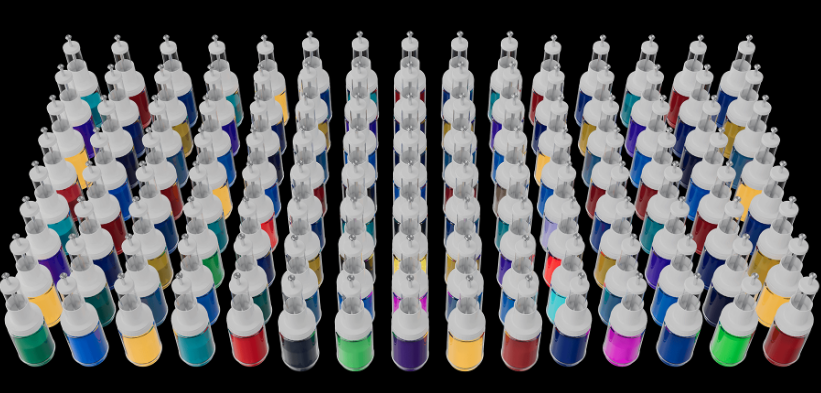

ELIAR LABx product family can be configured with a solution capacity of 40, 80, 120 or 160, taking into account parameters such as the dyestuff types you use in your enterprise, the color variety you will apply and the type of material to be dyed. Eliar LABx manages the processes of weighing the textile material to be dyed and preparing the dyestuff solutions. Following the preparation process, it prepares a total of 1.100 daily recipes in order to apply your recipe exactly, thus ensuring the right result in one go.

In dyeing processes, dyestuffs, chemicals and minerals are always prepared with the principle of mass measurement. It is of critical importance in terms of both precision and reproducibility that laboratory studies, which will turn into production recipes in the next stages, are carried out with the gravimetric principle.

ELIAR LABx uses individual syringes for each dyestuff solution included in the automation system. In this way, time is not lost with syringe cleaning and both serial and parallel dosing continues uninterrupted. Since the cleaning step is completely eliminated, critical risks such as mixing of dyestuff solutions in the syringe are also eliminated. ELIAR LABx provides a unique laboratory dosing experience as it does not require syringe calibration thanks to its multi-syringe technology.

Thanks to the main dosing robot and 2 additional robots working simultaneously on different axes, ELIAR LABx carries out the water filling, salt dosing and dyestuff solution dosing steps at the same time and feeds 24 separate dyeing tubes uninterruptedly. Thus, all possible waiting times are considered as active dosing times. ELIAR LABx has been designed in a structure that allows dyestuffs to be grouped and to define different mixer speeds for these groups.