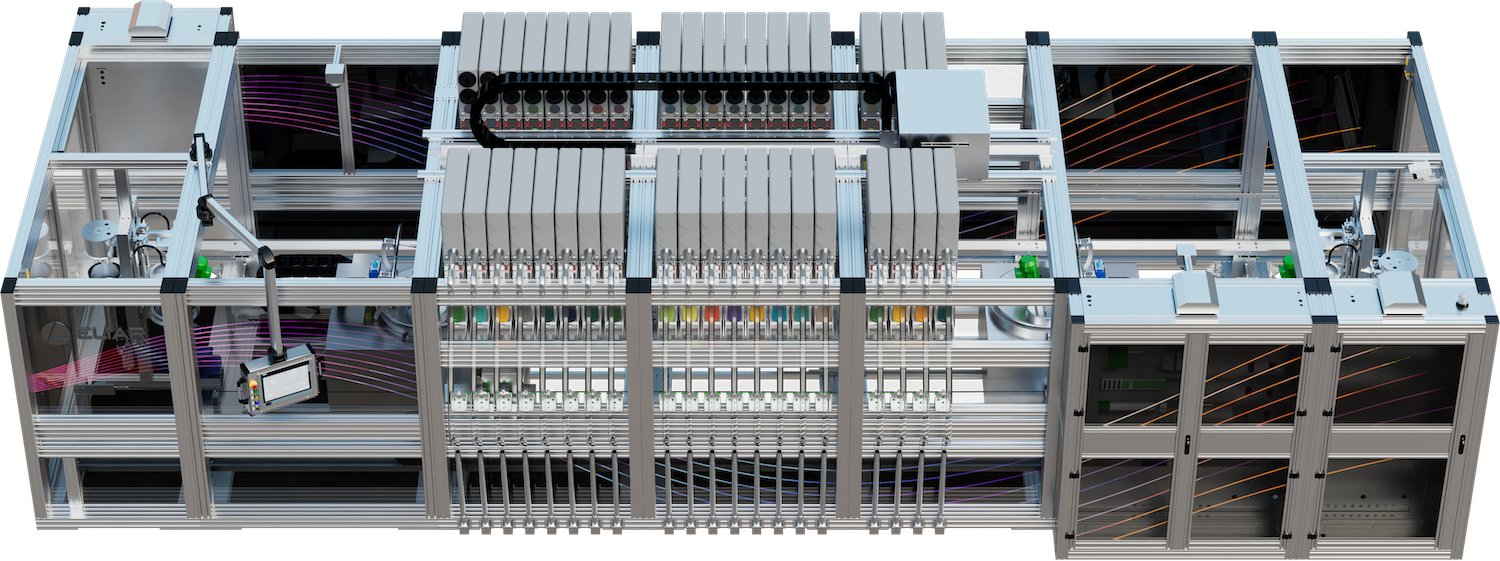

ADW, produced with the engineering and assurance of Eliar, has been developed to perform fully automatic textile dyeing processes and is the most precise and flexible of the powder dyestuff automation systems serving for this purpose.

Considering the diversity and consumption amounts of dyestuffs used in textile dyeing processes, it is extremely difficult and risky to carry out weighing, dissolving and distribution processes manually.

As a result of incorrect calculations, wrong dyestuff selection and under or over weighing, which are frequently encountered in manual processes, your final product quality and repeatability will decrease, and your production costs will increase exponentially.

In order to avoid all these problems, Eliar offers ADW, the most precise and flexible full automatic dyestuff weighing, dissolving and distribution system, specially developed for textile enterprises.

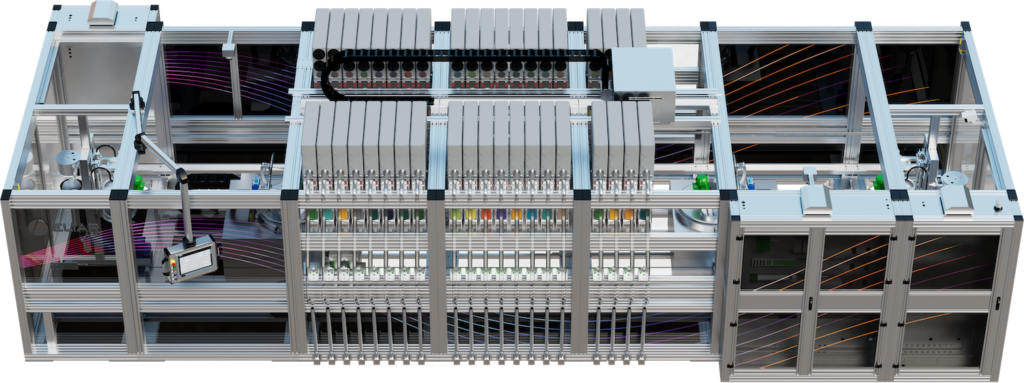

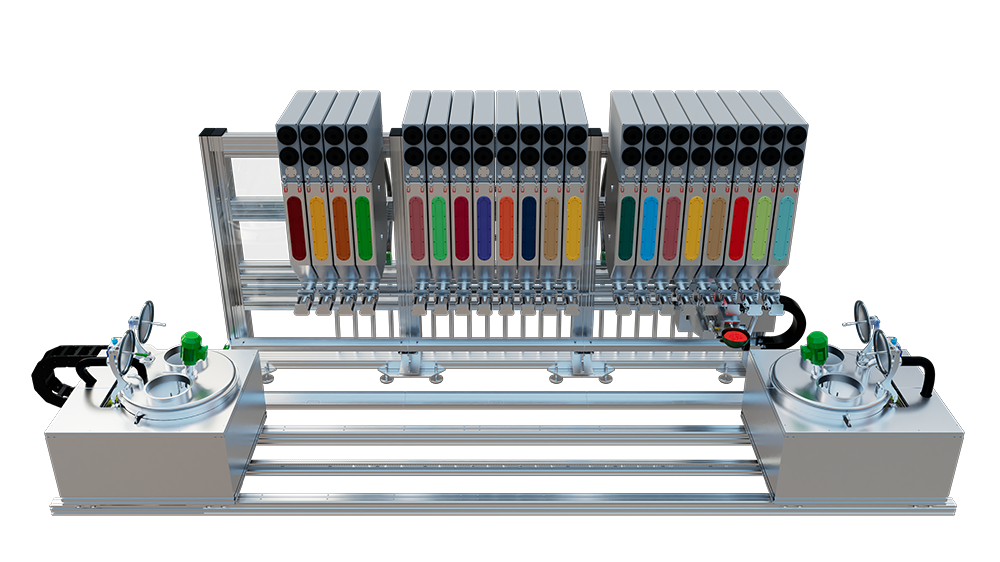

ADW has been designed with a modular dyestuff storage system that can be configured according to the needs of your factory, and thanks to this flexible structure, it can be configured with variable silo numbers from 16 to 80. With the strength of the stock silos used in ADW, each with a volume of 90 liters, suitable for dyestuff storage, designed using stainless and aluminum materials, the perfect and trouble-free storage of dyestuffs is guaranteed.

Eliar, which is among the world leaders with the products it produces for the textile industry, ensures that all dyeing processes are maintained with maximum efficiency with the ADW it has developed.

With ADW, you can have a production line where you can easily control your powder dyestuff consumption, guarantee perfect precision in all dyestuff weighing and dissolving processes, and at the same time completely eliminate errors and all potential accidents.

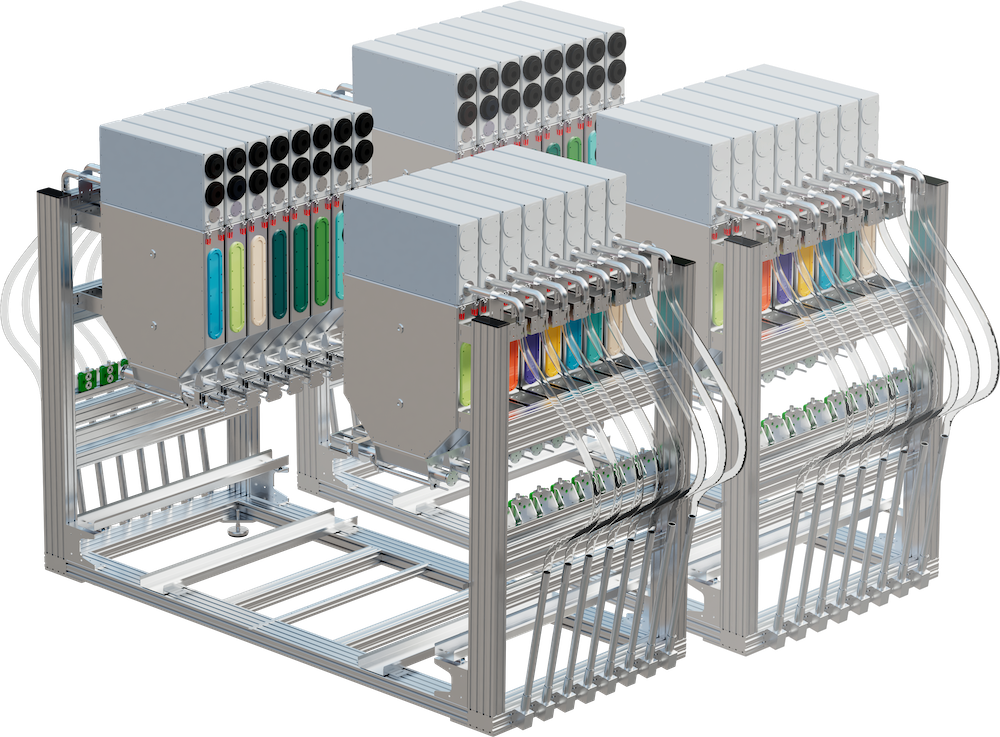

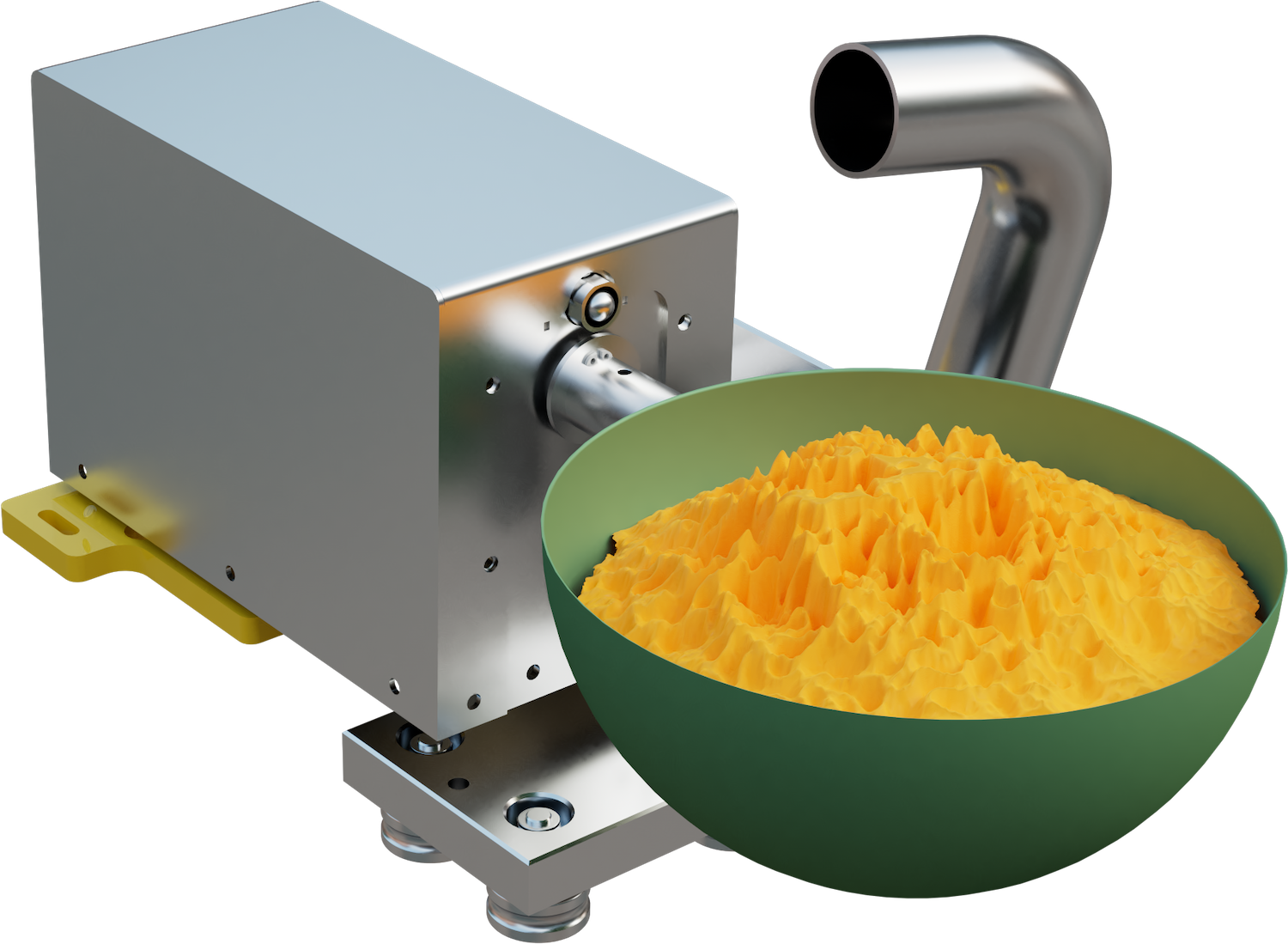

ADW carries out the weighing of the dyestuff with two weighing scoops positioned opposite each other on the horizontal axis, thus allowing two different dyestuffs to be weighed at the same time. Weighing is carried out with customized and high precision loadcells integrated into each scoop. When the relevant dyestuff request reaches ADW, the weighing scoop is positioned in the relevant silo. Then, the screw feeder carries the dyestuff flow from the silo to the weighing scoop.

ADW has been designed with dust prevention system integrated with the weighing scoops. While the dyestuff flows from the stock silo to the weighing scoop, a controlled vacuuming is carried out with the anti-dust system integrated into the scoop mechanism, and thus, dusting that may occur during weighing is prevented.

After the weighing scoop carry out the weighing of the dyestuff in the relevant recipe, the scoop is positioned in the washing and drying station to be ready for the next weighing. After the washing and drying process in this station, the scoops are immediately getting ready for a new weighing.

ADW is equipped with two moving dissolving robots, each with a volume of 110 liters, so it has the ability to prepare two different dyestuff recipes at the same time. Thanks to the customized design of the dissolving robots, each dissolving robot is able to take the weighed dyestuffs in the silos opposite to each other. When the relevant dyestuff request in your dyeing recipe reaches ADW, while the weighing bucket moves to the relevant stock silo, the mobile dissolving robot simultaneously approaches the silo where the scoop will weigh.

While the weighing scoop carries out the dyestuff weighing process, the dissolving robot takes water according to the dissolving scenario of the relevant dyestuff recipe and getting prepared for the dissolving process. After the weighing is completed, the lids of the dissolving robots are closed, and the dissolving process is carried out with the mixer.

The water to be used in the dissolving process is always at the required temperature for dissolving, thanks to the external water heating system. According to the dissolving parameter to be used in the relevant process, the temperature of the water to be taken into the dissolving tank is controlled by the internal temperature sensor, thus ensuring the optimum dissolving temperature.

After successfully dissolving and transferring each recipe, ADW dissolving robots automatically clean themselves and are ready for the next recipe. Thanks to its smooth SS316L inner surface and teflon-coated top cover structure, surface tension is minimized and the dyestuff remaining in the dissolving system is easily cleaned with the special hot water spray/washing system.

The loss of even individual dyestuff particles affects the final product color quality and reproducibility, as so, ADW also transfers the cleaning water to the dyeing machine add-on container to ensure complete transfer of the dyestuff that has been weighed and dissolved accurately.

ADW is integrated with ELIAR multi-line robotic distribution system. There are two distribution unit options with 15 and/or 22 outputs. With the option to use an additional distribution unit, ADW meets the dyestuff distribution needs of 44 dyeing machines. ELIAR, with its multi-line robotic dispensing technology and just-in-time dispensing discipline, guarantees to distribute the right dyestuff to the right machine, at the right time, without any risk of color mixing.